Energy loss, exhaust air re-entering supply air duct.

What are the Effects of leakage on energy and greenhouse gas emissions?

Despite the view expressed in AS 4254:2002, a few simple calculations suggest that there is a reason for concern about the impact of duct leakage. Consider a typical air conditioning system in which the designer follows and assumes a supply duct leakage rate of 5%. To deliver the designed air quantities to the spaces served, the fan must handle 1/0.95 times the sum of the room air quantities or 105% of the nominal air flow. Applying fan laws gives an increase in fan power of 117%, so the widely accepted leakage rate of 5% has added 17% to supply fan energy, for every hour the plant operates. At 10% leakage, the extra fan energy is 37%. This isn’t the end of the story because air leakage also affects cooling and heating plant energy consumption. The size of the effect depends on where the duct is located. If the duct is in the conditioned space and the leakage percentage is low, one might argue that nothing needs be done, that is, that the fan can safely supply 100%, not 105.3% of design because the leaked air produces useful cooling or heating inside the building envelope. This is not the case if the duct is in a ceiling return air plenum, as the leaked air will travel around the system producing minimal useful cooling and heating effect while increasing fan power and reducing return air temperature slightly.

If the supply duct is outside the conditioned space, such as in a ventilated roof space, the assumed leakage is simply lost and the 17% increase in fan power is compounded by 5% waste in cooling and heating effect and a corresponding increase in greenhouse gas emissions.

The analysis for return air ducts also depends on where the return air duct is located. If the duct or riser is in the conditioned space, leakage has little or no effect since the air leaking into the duct is the air that would have been returned anyway. If the return air duct is outside the conditioned space, the effect is even more serious.

Assume that under normal (non-economy cycle) operation the plant handles 15% outside air, in which case return air will be 85% of design supply air. Leakage at the rate of 5% into the return air duct will thus be 5% of 85% or 4.3% of the design supply air. If the air that leaks in is from outside of the building, it adds to the outside air load, the outside air percentage becoming

15% + 4.3% =19.3% of the supply air. Since the outside air load is pro rata, the outside air load increases by 4.3% / 15% = 28%. For a typical comfort cooling plant in Sydney, 15% outside air would be about 18% of the peak cooling capacity, so the leaked outside air will add 28% * 18% = 5% to the peak cooling load. In summary, a 5% leakage rate implies 17% increase in fan power and fan energy on the supply side plus 5% additional cooling and heating energy if the leakage is going to the outside the conditioned space plus another 5% waste in heating and cooling energy on the return side if it increases the outside air percentage. The combined effects of these will depend on the detail of the system. It will have less effect on a VAV system with an economic cycle but more on a constant volume system with a lower percentage of outside air. For example, it is not unreasonable that a modest 5% leakage rate could add 10 or 15% of operating energy and greenhouse gas emissions.

We do not have published data for the effect of duct leakage in Australian systems, but there have been some overseas studies dealing with the issue. One estimated the heating energy wasted by duct leakage in Belgium at 15 GW.h (0.054 PJ) per annum and 0.75 TW.h ((2.7 PJ) per annum for the rest of Europe (excluding the former Soviet Union). Another study of VAV systems in large commercial buildings in California [6] calculated that, compared to “tight” duct systems (2.5% leakage), systems with 10% leakage had

annual HVAC system operating costs 9 to 18% higher, while those with 5% leakage used 2 to 5% more energy.

In humid areas, the leaks in supply duct can result in condensation which accelerates the deterioration of the sheet metal. The same applies to kitchen exhaust where hot and humid air leakage moves into cool spaces.

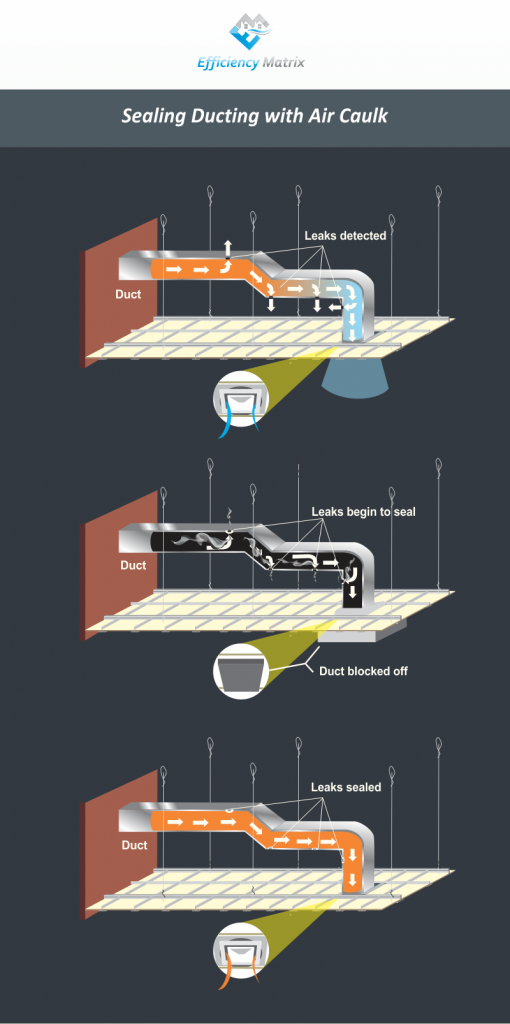

The major problem with the performance of the duct systems comes from the air not being efficiently delivered to the occupied space. Short-circuiting of conditioned air is another common issue in leaky ducts where supply air entered the return stream by passing the occupied zone.